OC Centrifuges For Filter-Less Oil Filtration

The Oil Cleaning Centrifuge (OC) is a filter less, high-speed centrifuge for removing of removing solids such as soot and liquid contaminates to less than 1 micron.

Centrifuge Clean Oil means

- Extending life of engine wear parts,

- Extending oil change intervals and reduces emissions.

- Extend the life of oil filters. No filters to stock. No disposal issues.

- OC is powered by engine oil pressure.

- Gear pumps are used for commercial or industrial applications.

The OC Series is installed on diesel, natural gas, and gasoline engines.

OC 250 CENTRIMOUNT IS EASY TO INSTALL NO RETURN HOSES. THE OC HAS NO CONSUMABLE PARTS OR FILTERS AND IS CAPABLE OF REMOVING SUB-MICORN PARTICLES

Filtration Fact. Diesel engines produce carbon soot during the combustion process. Soot concentrations will reduce the effectiveness of the anti-wear additives in the lubricating oil and cause increased engine wear. Standard 40-micron, surface-type, full-flow filters will not remove all of the carbon soot particles.

OC Centrifuge Benefits OF Micron Clean Oil

How The OC Centrifuge Works

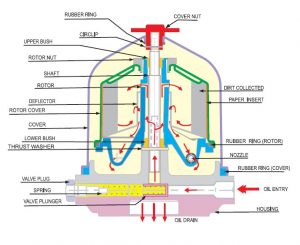

Principle of Operation

- The oil from a pressure port on the engine or from a gear pump is feed though the inlet of the OC.

- When the pressure exceeds 30 PSI the spring-loaded plunger will push back allowing oil to enter the rotor assembly through the central spindle.

The rotor assembly has two tangentially opposed nozzles at the base. The action of the oil exiting though the nozzles provide a counter rotation spinning of 5000 to 8000 rpm - Optimum results are achieved at 70-80 PSI. For example, the OC 50 operating at 70 PSI produces 7400 RPM which generates centrifuge force 2000 times that of gravity.

- The clean oil is retuned under gravity though the exit hole in the base. On CAT 3500 and Cummins 855, KTA/QSK 19, 38 & 50 the proprietyCentriMount casting with internal channels which returns the oil to the engine oil supply.

- Any particles heavier than the oil -soot etc., is compacted onto the inner rotor bowl and at predetermined intervals is easily removed. A spare rotor assembly enables rapid change time.

OC CentriMount

The CentriMount was introduced initially for marine applications to provide a compact, simpler and cost-efficient installation using the engines existing inspection ports. The CentriMount design eliminated as much as possible the potential for leaking or breaking an oil return hose.

The clean oil is returned to the engines oil supply through the internal channel in every casting.

Internal oil return channels on CentriMount for the KTA 19 and Cat 3500

Simply the best Centrifuge. No parts to replace. No filters

- Inlet with ball valve to shut down flow to change out dirty rotor assembly & pressure gauge for pressure check.

- Shows spindle that deliver the dirty oil to the centrifuge rotor chamber. Bearings are self-lubricating: not requiring replacement. The Interior is electro less nickel plated for longer wear

- Opposing oil jets under pressure 80 psi spin the rotor more than 8000 rpm.

Cummins Marine Engines OC Centrifuges CentriMount

C-9 OC 20 with Valve Cover CM

855 Marine OC 20 CM

QSK 19 OC 50 CM

KTA 19 OC 50 CM

Installed OC 50 CM on KTA 19

CM 38 KTA/QSK Engine

CM 38 KTA/QSK Engine

OC CAT Marine 3500 Series

Major NY based ship assist tug operator installs OC 250 CentriMount's on CAT 3500 Series Engines. ROI ranges from 4 months to 8 months depending on operating hours. Safely extended oil changes from 1000 hrs. to 1500 hrs. First install 2010 no replace parts required.

Land Fill Methane GAS Powered

OC 500 Jenbacher

CAT 3520 & OC 250 CM

Other Typical Installations

Lugger OC 50

C-19 OC 50

OC 500 Oil Polisher

Power Gen

Off Road & Mining

RioAlto Mining Installed OC 50 on CAT 777 Fleet