Early Warning Sensor Technology Group Monitoring Products

It’s All About Chemistry.

The Tan Delta oil and fuel quality monitoring systems uses advanced technology to accurately monitor the quality of oil and fuels in real-time. The chemical composition of all oils and fuels change as they wear and/or become contaminated, therefore accurate and reliable monitoring of the chemical profile of oils and fuels enables a complete, true understanding of their current condition.

All oils and fuels have an optimum standard chemical fingerprint which can be analyzed and profiled. This profile provides a firm reference point from which deviations can be measured and the associated quality changes determined. Accurate measurement of the chemical fingerprint of the oil at any given point in time and referencing the deviation from the original gives a very precise view of the current quality.

The key aspect of measuring the chemical profile of oil or fuels is to look at the overall quality and to not focus on the individual elements such as oxidation, moisture, and/or contamination. As degradation is effected by a combination of these factors the Tan Delta patented sensor technology ensures that you get an accurate overall view of the current status of the oil or fuel.

For every type of oil and for each individual application, deviation from the optimal is a critical and necessary measurement in determining when a change or service is required. Accurate real-time monitoring enables simple trend analysis which is then used to identify potential problems long before any damage to equipment or reliability compromises occur. The same data is also used in a predictive manner to forecast when servicing is required, based on the actual condition of the oil and therefore servicing schedules are set due to need rather than an outdated standard service schedule.

The Oil Quality Sensor

The patented Oil Quality Sensor is inserted in the oil stream and passes a low voltage electric current through the oil and measures the conductance and capacitance ratio (patented) to determine the oils electro-chemical make-up and therefor the oils lubricating quality. As oil is used, polar particles will build up causing the conductance and capacitance ration to change once this valve has fallen by generally at 30% the oil will no longer perform at an acceptable level.

TAN DELTA MONITORING & COMMUNICATIONS PRODUCTS

Patented Oil Quality Sensor - Core Product - is now able to deliver real time oil condition data to the following monitoring and communications devices.

Express Monitor - Engine Kit - QQS + Express + CADS (Configuration & Data Software) + Data Cables

Express System

Wifi Android

Advanced Technology

PROFESSIONAL 4 OQS KIT

OQD Professional Display and 4 Oil Quality Sensors. A complete kit enables quick and simple installation and is ideal for applications that require multiple sensors. It includes professional display, 4 Oil Quality Sensors and all of the necessary cables for configuration and installation including the robust OQD Professional Hub.

New GATEWAY 10 OQS Wifi System.

Monitors up to 10 Oil Quality Sensors

The Oil Quality Gateway (OQTg) has been developed to enable online monitoring and alerting of up 10 assets. The OQTg offers you multiple connectivity paths to the TD online monitoring service….mobile data, WiFi and/or Ethernet networks.

New TD Online Monitoring Service

The large dial is oil condition - life remaining-based on Tan Delta oil quality scale. In this case, the oil is new. Top left dial shows oil temperature and right dial shows internal temperature.

The large dial is oil condition - life remaining - based on Tan Delta oil quality scale. In this case, the oil is new.

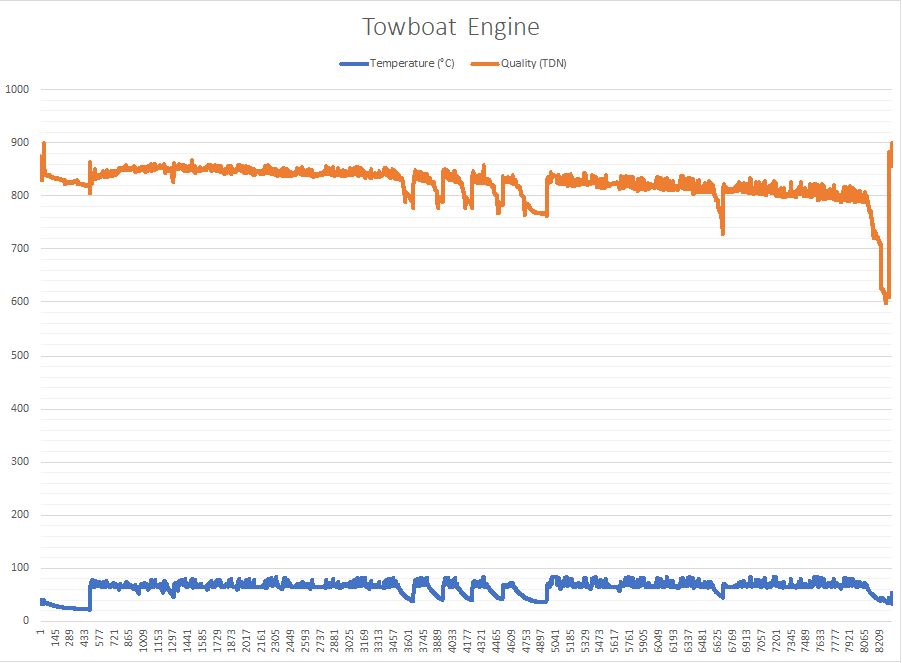

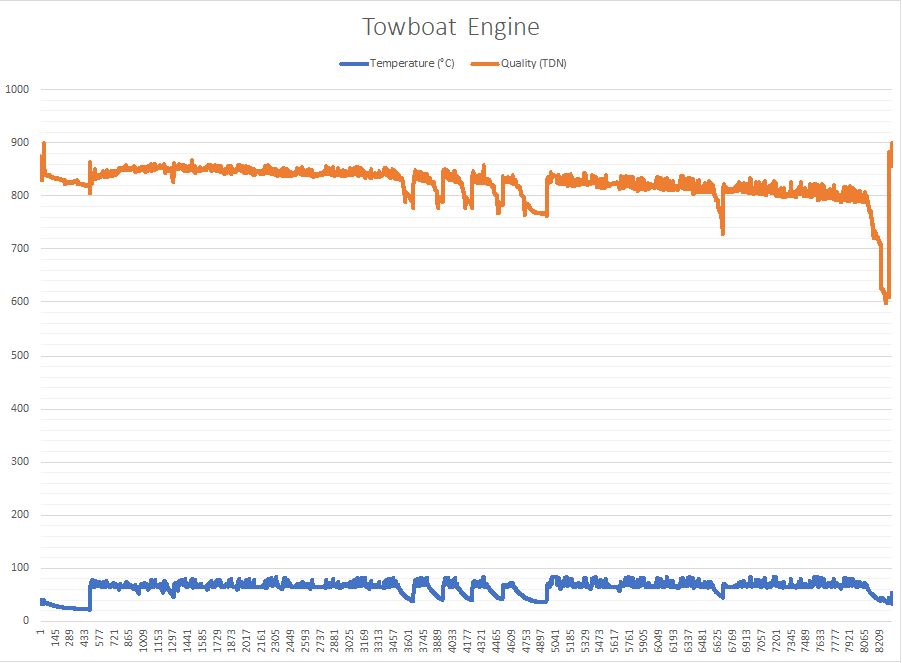

Data Analysis - Actual Data

CADS provides you with tools such as trend analysis to maximize the benefits of your oil monitoring data.

CADS - Calibration & Data Software

- Flexible Configuration - Enables the simple and easy configuration of all Tan Delta products to suit any applications with any oil type.

- Data Analysis - CADS provides you with tools such as trend analysis to maximize the benefits of your oil monitoring data.

- Oil Database - Comprehensive database of oil configuration profiles for Oil Quality Sensor (OQSx) performance optimization.

- Automatic Updates - Any necessary database

Mobil Oil Test

Test multiple oil samples in the field or plant.

- Fully Configurable Any oil type, MOT allows accurate testing of any oil or fuel oil.

- Instant Results. Instant diagnosis of potential issues with the ability to store trend data.

- Fully Certified. The Oil Quality Sensor (OQSx) is fully certified to international standards to work in the majority of commercial and industrial applications.

- Robust and Rugged. Housed within a rugged industrial quality IP67 rated case, ideal for throwing in the back of you service vehicle and carrying on site.

- All You Need. Everything your engineers need to undertake instant oil analysis in one place.

Data Analysis/Actual Data